Precision in mould making Klaucke & Meigies improves mould production with high-tech EDM machines

Related Vendors

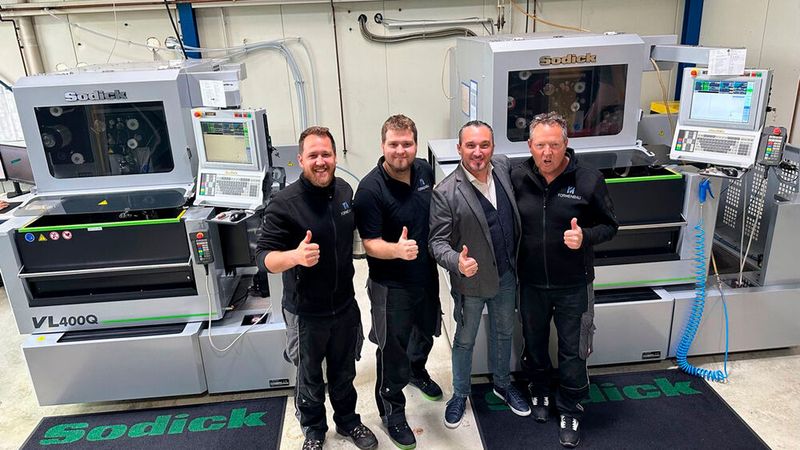

Tool and mould maker Klaucke & Meigies has invested in new Sodick EDM machines. The purchase of the new machines will ensure fast processes and increased throughput despite a full order book.

The German mould maker Klaucke & Meigies has been in business since 1994 and will celebrate its 30th anniversary next year. Starting in smaller rented premises, the company built its own production halls in a new industrial area at the turn of the millennium. From the outset, it has made sure that the industrial floors spotless and the machinery is always up to date. “When you walk into a production facility and see machines with that standard green industrial colour, then there is a need for investment. At our company, you only see such green machines in the grinding room,” says Managing Director Jan Meigies. “Our machines also impress the customers time and again.”

Klaucke & Meigies mainly builds plastic injection moulds and serves around 500 customers from a wide range of sectors, including the automotive and railway industries and pump manufacturers. A large number of thermoplastic moulds are supplied to the electrical supply industry for the manufacture of switches, sockets and much more. Long-standing customers include Wilo and Vossloh. For the latter, Klaucke & Meigies has already built moulds for China and Kazakhstan. “And if a customer wants me to, I will fly there to help commission a mould on site,” says Jan Meigies with pride. “In some cases, we also train the local staff in the maintenance or modification of the moulds.”

Sign in or register and read on

Please log in or register and read this article. To be able to read this article in full, you must be registered. Free registration gives you access to exclusive specialist information.

Already registered? Log in here

:quality(80)/p7i.vogel.de/wcms/8d/b7/8db71c3fe25cd48399bfd8faaa5e90f7/0129228188v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/44/fc4431baf22faf49f91d695e7725b0de/0129227575v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/49/58/4958084fe5c4ed0a7758f7cfb3051e92/0128854986v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/39/ad3982b17d8034c9134821a24e023d12/0128991046v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/34/2f344c97b0e4a9613850f3bb3b519101/0129337496v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/8c/528c3c99265c6d8951e6bb1dcf4ed7c2/0129224981v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/28/95/28952358db60b91461ebfda8196fad46/0129221819v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d0/bd/d0bd3f70a8063a08274ed663509a1053/0129219028v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5d/3c/5d3cd553a019b4033e441e61f98b23d6/0129229293v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/82/e7/82e72d20cefdef73713b584312be57d0/0129209599v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/76/5276fd0bc681a34a30c4d7dc0ac4784c/0129107063v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d6/f8/d6f8f7b5bc0b08eb7357806e4b4d6df3/0128993006v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ae/7c/ae7cfa25bd4cbdee97cf91514a80a569/0129333424v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/50/7e/507e92bc6eb96c6646801c23695fd698/0128867905v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/8c/cd8c3ca788be29055f3af26645fa0262/0128810840v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/59/4059f2264fa9693e048ee11050839486/0128700610v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/74/07746815a405db2865052931aa3b9655/0129103565v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/05/11/05119b92ebfd03919d063b254eec1b27/0129056177v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/5d/9b5db33353f3e5a256e2f634ddc349c7/0129333056v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/e1/0ae1b7a9cc45bf10ebcbce27be707eda/0129230371v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f4/e9/f4e9eabb65e0b34fe9911620718ea8e2/0129055594v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ba/7b/ba7bc9220708dc4bd16b8c815db267c2/0128938301v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/ca/f9ca9cace88200a5ec0946f193264963/0129209504v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/61/2f61dd20be68049fa2320a2e5aa860d7/0123789183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c5/49/c54973f28495dada1c7605f913717341/0121533734v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/8f/948f81f46645691d1d90152ef605a0ae/0120806008v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3e/fb/3efbcc73e59a0c19de0676cf569c6f28/0129201505v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/59/9e59861a06c0d20831e0d7d5191188ed/0129056166v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/41/93/4193f3985dc04080399cb574e810a79c/0128985792v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ce/94/ce94bd1d0acf451687549f8e3efdb07a/0128981060v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/3e/4a3ee5cd13d05629db9d3e88aa22ff01/0129103256v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/b4/6bb456c148f06af9d65155da63665c22/0129102929v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4d/f34d32adcd63bdf5332e4d57ae75611a/0128850501v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7c/a2/7ca2adf016cad8d1de510c4df0ff57bc/0128810813v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/57/9c/579c8e2bcff2e800a19fcb0926e574fa/0129056117v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/5f/4a5fd6bde5784db58812f15386c2126f/0126112832v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/3c/873c56a315b598e5491cef38d9ef72f1/0123364440v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/00/2a/002ad74723b737fd6e4729e3434f16ab/0123040413v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/9c/6b9cab1e262f77caed8179ed3dc29807/0129104421v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/a3/39a32d830d6bb6e4471c79e537c5ca52/chimei-ecologue-frosch-6000x3373v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/29/2b297a2773f13d3017fc6d49424a57b1/0127570680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/13/ec/13ece74e59d459301ea38becf80c9706/0129200881v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fe/9b/fe9b79ee842142ff26180132de72b2d5/0129103360v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/7e/2a7e5ced0986e88a6c24123fba954dee/0128871141v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/2a/1d2a6bc382131d8cc1f325617e1dced8/0128870377v1.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/125700/125705/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/64200/64280/65.png)

:quality(80)/p7i.vogel.de/wcms/2f/61/2f61dd20be68049fa2320a2e5aa860d7/0123789183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/22/0e/220efd3f7f8f358b48a574bf0eec4ea7/0128664282v3.jpeg)