Efficiency boost Latest innovations in hot-runner technology

Related Vendors

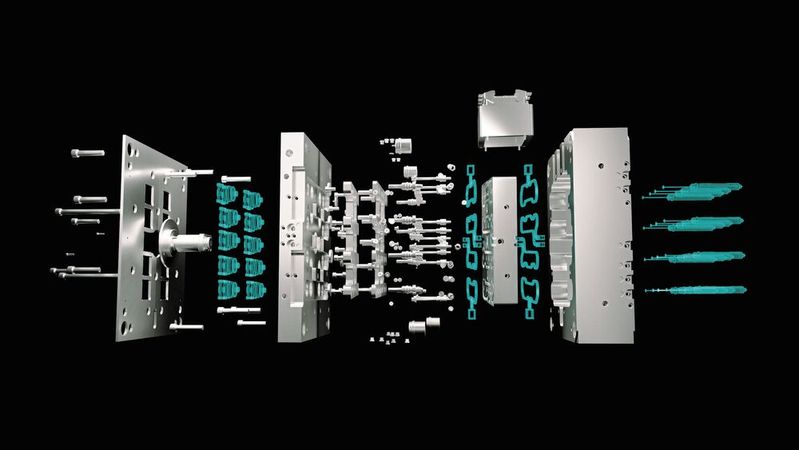

Hot runner manufacturers have introduced a range of innovative products and solutions in 2024, designed to improve injection moulding processes. Their advancements focus on boosting efficiency, reducing waste and increasing production flexibility.

Husky will be participating at Fakuma 2024, which will take place in Friedrichshafen, Germany, from October 15 to 19. With a growing emphasis on sustainability and technological innovation, the company aims to support producers and mould makers in Germany, Europe, and beyond, helping them remain competitive in today’s evolving market.

At the exhibition, Husky will showcase a range of technologies, solutions, and services that cater to the packaging, medical device, and mould-making industries, with a focus on achieving sustainability, growth, flexibility, and profitability. Among the featured offerings will be the latest advancements in Husky’s Altanium mould controllers, which include the company’s innovative Active Reasoning Technology (ART 2.0). The company will also highlight its Ultramelt hot runner system, designed for efficient and sustainable moulding processes, particularly with bioresins and other materials.

Sign in or register and read on

Please log in or register and read this article. To be able to read this article in full, you must be registered. Free registration gives you access to exclusive specialist information.

Already registered? Log in here

:quality(80)/p7i.vogel.de/wcms/8d/b7/8db71c3fe25cd48399bfd8faaa5e90f7/0129228188v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/44/fc4431baf22faf49f91d695e7725b0de/0129227575v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/49/58/4958084fe5c4ed0a7758f7cfb3051e92/0128854986v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/39/ad3982b17d8034c9134821a24e023d12/0128991046v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/34/2f344c97b0e4a9613850f3bb3b519101/0129337496v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/8c/528c3c99265c6d8951e6bb1dcf4ed7c2/0129224981v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/28/95/28952358db60b91461ebfda8196fad46/0129221819v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d0/bd/d0bd3f70a8063a08274ed663509a1053/0129219028v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b7/e0/b7e0832ad0be13fb559a7028f2ef02c7/0129386806v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5d/3c/5d3cd553a019b4033e441e61f98b23d6/0129229293v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/82/e7/82e72d20cefdef73713b584312be57d0/0129209599v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/76/5276fd0bc681a34a30c4d7dc0ac4784c/0129107063v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ae/7c/ae7cfa25bd4cbdee97cf91514a80a569/0129333424v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/50/7e/507e92bc6eb96c6646801c23695fd698/0128867905v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/8c/cd8c3ca788be29055f3af26645fa0262/0128810840v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/59/4059f2264fa9693e048ee11050839486/0128700610v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/74/07746815a405db2865052931aa3b9655/0129103565v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/05/11/05119b92ebfd03919d063b254eec1b27/0129056177v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/5d/9b5db33353f3e5a256e2f634ddc349c7/0129333056v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/e1/0ae1b7a9cc45bf10ebcbce27be707eda/0129230371v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f4/e9/f4e9eabb65e0b34fe9911620718ea8e2/0129055594v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ba/7b/ba7bc9220708dc4bd16b8c815db267c2/0128938301v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/ca/f9ca9cace88200a5ec0946f193264963/0129209504v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/61/2f61dd20be68049fa2320a2e5aa860d7/0123789183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c5/49/c54973f28495dada1c7605f913717341/0121533734v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/8f/948f81f46645691d1d90152ef605a0ae/0120806008v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/04/3d/043d3f95c300d98d7188d2c2f0673aa5/0129365083v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/9e/0b9e9ae6c55036cf35f97cd4ffca9d27/0129363249v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3e/fb/3efbcc73e59a0c19de0676cf569c6f28/0129201505v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/59/9e59861a06c0d20831e0d7d5191188ed/0129056166v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/3e/4a3ee5cd13d05629db9d3e88aa22ff01/0129103256v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/b4/6bb456c148f06af9d65155da63665c22/0129102929v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4d/f34d32adcd63bdf5332e4d57ae75611a/0128850501v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7c/a2/7ca2adf016cad8d1de510c4df0ff57bc/0128810813v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/57/9c/579c8e2bcff2e800a19fcb0926e574fa/0129056117v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/5f/4a5fd6bde5784db58812f15386c2126f/0126112832v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/3c/873c56a315b598e5491cef38d9ef72f1/0123364440v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/9c/6b9cab1e262f77caed8179ed3dc29807/0129104421v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/a3/39a32d830d6bb6e4471c79e537c5ca52/chimei-ecologue-frosch-6000x3373v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/29/2b297a2773f13d3017fc6d49424a57b1/0127570680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/fd/07fd8752b8d884ee69baba1b2207d82d/0129373572v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/13/ec/13ece74e59d459301ea38becf80c9706/0129200881v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fe/9b/fe9b79ee842142ff26180132de72b2d5/0129103360v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/7e/2a7e5ced0986e88a6c24123fba954dee/0128871141v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/66/0e/660e93698db24/hasco-logo-or-b50.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/125700/125705/65.jpg)

:quality(80)/p7i.vogel.de/wcms/22/0b/220bb75660b86b93f2188070cfb3da7b/0125957986v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cf/76/cf76db55ed7bd91ad2ad317c323d66f9/0125384025v1.jpeg)