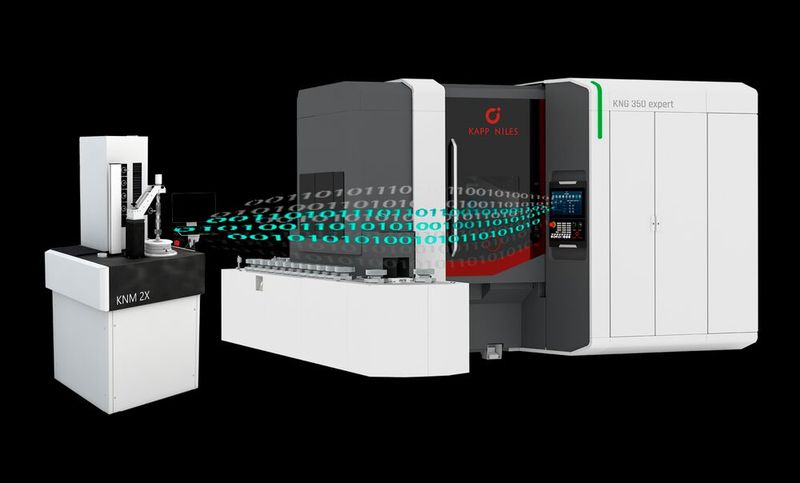

Digitalisation Data-driven innovations propel grinding technology into the IoT era

Related Vendors

As the precision of grinding machinery and tools approaches physical limits, the focus shifts to optimising processes and embracing IoT connectivity. With the spotlight on secure data sharing and the customisation of digital solutions, industry leaders are paving the way for seamless integration and enhanced performance.

The digitalization of production processes, including those involving grinding technology, holds high expectations. We are approaching the physical limits in terms of grinding machine and tool precision. Accordingly, attention is now shifting towards process optimization and networking in the IoT (Internet of Things) as means of opening up new development potential. Scientists and industrial companies have expressed a common desire to engage in cooperation and networking. However, organizations are keen to retain control over their data, which is likely to play a decisive role in raising trust levels and acceptance, especially in medium-sized companies.

Process data is a valuable asset. “Awareness levels have risen considerably in recent years,” confirms Alexej Voigt, head of Electrical Engineering at grinding machine manufacturer Danobat-Overbeck, Herborn. He gave a talk at the most recent Schleiftagung conference in Stuttgart-Fellbach, held at the end of January. There he discussed the potential of machine data analysis for grinding process optimization and also outlined methods for data acquisition and analysis in digital motor spindles.

Sign in or register and read on

Please log in or register and read this article. To be able to read this article in full, you must be registered. Free registration gives you access to exclusive specialist information.

Already registered? Log in here

:quality(80)/p7i.vogel.de/wcms/d2/63/d26376330f084c718f9ab83fc66eb39f/0129319680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/a9/4fa94db21a092a12fdb0822e3d5c8150/0129504798v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/8d/b7/8db71c3fe25cd48399bfd8faaa5e90f7/0129228188v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/44/fc4431baf22faf49f91d695e7725b0de/0129227575v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ba/ea/baea897f2d161c46f0872c77cd26fb6b/0129039787v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a6/06/a606d5e06236baca21d7f53019dedf42/0129504701v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/a8/0ba81aaff9b06473404eafd31bfbfe06/0129451471v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/34/2f344c97b0e4a9613850f3bb3b519101/0129337496v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/63/53/6353c75a9072fc20846b40065c12f724/0129533055v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b7/e0/b7e0832ad0be13fb559a7028f2ef02c7/0129386806v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5d/3c/5d3cd553a019b4033e441e61f98b23d6/0129229293v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/82/e7/82e72d20cefdef73713b584312be57d0/0129209599v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/84/24844705e911d0231a551255ab3a7ee7/0129505503v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ae/7c/ae7cfa25bd4cbdee97cf91514a80a569/0129333424v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/50/7e/507e92bc6eb96c6646801c23695fd698/0128867905v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/8c/cd8c3ca788be29055f3af26645fa0262/0128810840v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/59/6959edab3090fb6cf478998605b90f26/0129542165v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/c8/43/c843d8084b4db01b20506a3773a8e56d/0129505472v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/8c/528c3c99265c6d8951e6bb1dcf4ed7c2/0129224981v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/96/16/9616c2fc580d720e8b3f91bbffcc5a01/0129504787v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/5d/9b5db33353f3e5a256e2f634ddc349c7/0129333056v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/e1/0ae1b7a9cc45bf10ebcbce27be707eda/0129230371v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f4/e9/f4e9eabb65e0b34fe9911620718ea8e2/0129055594v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/ca/f9ca9cace88200a5ec0946f193264963/0129209504v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/61/2f61dd20be68049fa2320a2e5aa860d7/0123789183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c5/49/c54973f28495dada1c7605f913717341/0121533734v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/8f/948f81f46645691d1d90152ef605a0ae/0120806008v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/46/85/46854ab7a2679db67354f556f2bc1db9/0129539660v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/88/a2/88a2be18834640f6e34db6bcaa98da06/0129504771v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/04/3d/043d3f95c300d98d7188d2c2f0673aa5/0129365083v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/8b/54/8b54feb68d4c545e53445acd0f4ad451/0129553957v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/3e/4a3ee5cd13d05629db9d3e88aa22ff01/0129103256v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/b4/6bb456c148f06af9d65155da63665c22/0129102929v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4d/f34d32adcd63bdf5332e4d57ae75611a/0128850501v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/57/9c/579c8e2bcff2e800a19fcb0926e574fa/0129056117v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/5f/4a5fd6bde5784db58812f15386c2126f/0126112832v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/3c/873c56a315b598e5491cef38d9ef72f1/0123364440v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/9c/6b9cab1e262f77caed8179ed3dc29807/0129104421v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/49/58/4958084fe5c4ed0a7758f7cfb3051e92/0128854986v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/a3/39a32d830d6bb6e4471c79e537c5ca52/chimei-ecologue-frosch-6000x3373v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/29/2b297a2773f13d3017fc6d49424a57b1/0127570680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/fd/07fd8752b8d884ee69baba1b2207d82d/0129373572v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/13/ec/13ece74e59d459301ea38becf80c9706/0129200881v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fe/9b/fe9b79ee842142ff26180132de72b2d5/0129103360v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/7e/2a7e5ced0986e88a6c24123fba954dee/0128871141v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/66/0e/660e93698db24/hasco-logo-or-b50.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/118400/118496/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/64200/64280/65.png)

:quality(80)/p7i.vogel.de/wcms/8b/54/8b54feb68d4c545e53445acd0f4ad451/0129553957v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/53/4c/534c6d014c774c16846d6cbc79367966/0128062240v1.jpeg)