Hot runner systems supplement portfolio Tunnel gate inserts at the focus of the new i-mold

I-mold molding innovations has been re-founded under a known name as of 1 February 2022. CEO Andy Walter is now focusing the company on the patented tunnel gate inserts that are developed in-house for injection moulding tools.

Related Vendors

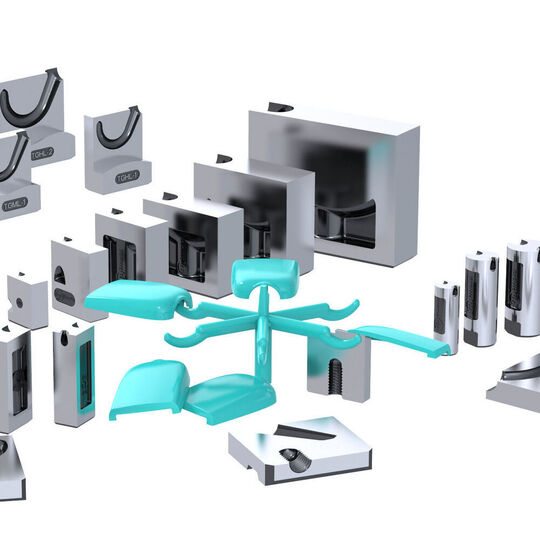

Tunnel gate inserts offer convenient solutions for applications in which mouldings — not recognisable from the outside — must be gated from the back or from the side, which is a particular advantage with visible areas. The gating point is then usually below the mould parting line so that it is unreachable with conventional gate designs. Tunnel gate inserts solve the problem by guiding the melt through the mould parting line to the gating point.

Andy Walter, CEO of the new I-Mold company, is focusing the portfolio on tunnel gate inserts for injection moulding tools. Hot runner systems from Heatlock round off the company’s product portfolio.

Andy Walter comments: “Over a period of 20 years, i-mold has collected the comprehensive knowledge for producing such inserts. The result is low-wear products with good flow properties that, even in changing temperatures, ensure a precise fit in the mold without any play.” Today, tunnel gate inserts from i-mold are being used in 33 countries across all sectors of the industry. He continues: “At present, the demand from our customers is for around 15,000 units a year, with the inserts being supplied in different geometries and dimensions. We see a continuously growing demand for the future, which we will meet with the help of our global network of distributors.”

The hot runner product range from Heatlock covers not only application-oriented nozzles but also fully integrated and wired hot runner systems, modular control units, and ceramic insulation to reduce the transfer of heat between the hot runner system and the mould plate.

(ID:48069414)

:quality(80)/p7i.vogel.de/wcms/d2/63/d26376330f084c718f9ab83fc66eb39f/0129319680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/a9/4fa94db21a092a12fdb0822e3d5c8150/0129504798v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/8d/b7/8db71c3fe25cd48399bfd8faaa5e90f7/0129228188v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/44/fc4431baf22faf49f91d695e7725b0de/0129227575v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ba/ea/baea897f2d161c46f0872c77cd26fb6b/0129039787v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a6/06/a606d5e06236baca21d7f53019dedf42/0129504701v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/a8/0ba81aaff9b06473404eafd31bfbfe06/0129451471v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/34/2f344c97b0e4a9613850f3bb3b519101/0129337496v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/63/53/6353c75a9072fc20846b40065c12f724/0129533055v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b7/e0/b7e0832ad0be13fb559a7028f2ef02c7/0129386806v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5d/3c/5d3cd553a019b4033e441e61f98b23d6/0129229293v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/82/e7/82e72d20cefdef73713b584312be57d0/0129209599v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/84/24844705e911d0231a551255ab3a7ee7/0129505503v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ae/7c/ae7cfa25bd4cbdee97cf91514a80a569/0129333424v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/50/7e/507e92bc6eb96c6646801c23695fd698/0128867905v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/8c/cd8c3ca788be29055f3af26645fa0262/0128810840v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/59/6959edab3090fb6cf478998605b90f26/0129542165v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/c8/43/c843d8084b4db01b20506a3773a8e56d/0129505472v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/8c/528c3c99265c6d8951e6bb1dcf4ed7c2/0129224981v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/96/16/9616c2fc580d720e8b3f91bbffcc5a01/0129504787v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/5d/9b5db33353f3e5a256e2f634ddc349c7/0129333056v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/e1/0ae1b7a9cc45bf10ebcbce27be707eda/0129230371v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f4/e9/f4e9eabb65e0b34fe9911620718ea8e2/0129055594v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/ca/f9ca9cace88200a5ec0946f193264963/0129209504v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/61/2f61dd20be68049fa2320a2e5aa860d7/0123789183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c5/49/c54973f28495dada1c7605f913717341/0121533734v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/8f/948f81f46645691d1d90152ef605a0ae/0120806008v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/46/85/46854ab7a2679db67354f556f2bc1db9/0129539660v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/88/a2/88a2be18834640f6e34db6bcaa98da06/0129504771v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/04/3d/043d3f95c300d98d7188d2c2f0673aa5/0129365083v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/3e/4a3ee5cd13d05629db9d3e88aa22ff01/0129103256v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/b4/6bb456c148f06af9d65155da63665c22/0129102929v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4d/f34d32adcd63bdf5332e4d57ae75611a/0128850501v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7c/a2/7ca2adf016cad8d1de510c4df0ff57bc/0128810813v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/57/9c/579c8e2bcff2e800a19fcb0926e574fa/0129056117v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/5f/4a5fd6bde5784db58812f15386c2126f/0126112832v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/3c/873c56a315b598e5491cef38d9ef72f1/0123364440v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/9c/6b9cab1e262f77caed8179ed3dc29807/0129104421v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/49/58/4958084fe5c4ed0a7758f7cfb3051e92/0128854986v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/a3/39a32d830d6bb6e4471c79e537c5ca52/chimei-ecologue-frosch-6000x3373v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/29/2b297a2773f13d3017fc6d49424a57b1/0127570680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/fd/07fd8752b8d884ee69baba1b2207d82d/0129373572v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/13/ec/13ece74e59d459301ea38becf80c9706/0129200881v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fe/9b/fe9b79ee842142ff26180132de72b2d5/0129103360v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/7e/2a7e5ced0986e88a6c24123fba954dee/0128871141v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/66/0e/660e93698db24/hasco-logo-or-b50.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/84400/84424/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/125700/125705/65.jpg)

:quality(80)/p7i.vogel.de/wcms/7a/8f/7a8fd0e2c47a69b277acef4536d5d25b/0126745996v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/72/06/7206b66cf114823a63472f893a95670a/0127349706v2.jpeg)