Hot Runner Technology Thermal simulation increases safety in hot runner technology

High-performance plastics with ever narrower windows of processing temperatures and more sensitive additives mean that the demands on hot runner technology are constantly increasing.

Related Vendors

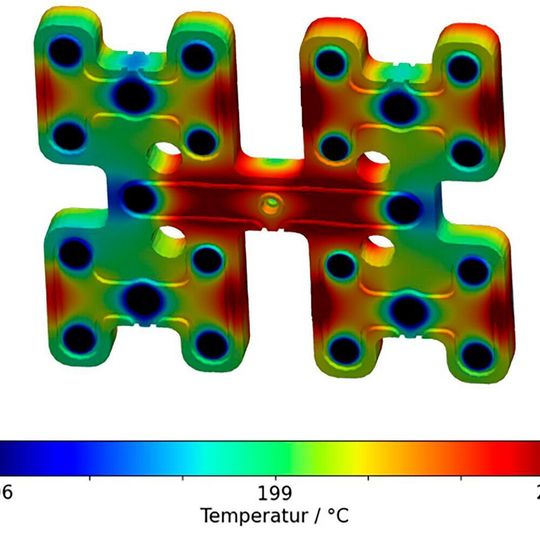

When moulding high-performance plastics, homogeneous temperature distribution in the hot runner manifold is just as important as a flat temperature curve in the high-performance nozzles. In the future, Hasco hot runner will offer its customers additional security with thermal simulation to meet these challenges. Thermal irregularities or hot spots are already detected during the design process and can be ideally designed by adjusting the heating curve and optimizing the position of the thermal sensor. Here, not only the temperature curve of the manifold is analyzed, but also the temperature curve of the plastic in the melt channel. Especially when processing temperature-sensitive plastics, the process reliability and thus also the production quality are significantly increased.

The new simulation tool is directly integrated in the design process at Hasco hot runner and enables an automatic and fast analysis. This avoids any loss of time in the creation of the 3D data and the customer receives the design data at the usual speed.

In combination with the already standard filling simulations and the experienced staff, Hasco hot runner offers its customers the best possible security for the individual challenges in hot runner technology.

(ID:48088828)

:quality(80)/p7i.vogel.de/wcms/8d/b7/8db71c3fe25cd48399bfd8faaa5e90f7/0129228188v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/44/fc4431baf22faf49f91d695e7725b0de/0129227575v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/49/58/4958084fe5c4ed0a7758f7cfb3051e92/0128854986v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/39/ad3982b17d8034c9134821a24e023d12/0128991046v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/34/2f344c97b0e4a9613850f3bb3b519101/0129337496v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/8c/528c3c99265c6d8951e6bb1dcf4ed7c2/0129224981v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/28/95/28952358db60b91461ebfda8196fad46/0129221819v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d0/bd/d0bd3f70a8063a08274ed663509a1053/0129219028v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b7/e0/b7e0832ad0be13fb559a7028f2ef02c7/0129386806v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5d/3c/5d3cd553a019b4033e441e61f98b23d6/0129229293v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/82/e7/82e72d20cefdef73713b584312be57d0/0129209599v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/76/5276fd0bc681a34a30c4d7dc0ac4784c/0129107063v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ae/7c/ae7cfa25bd4cbdee97cf91514a80a569/0129333424v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/50/7e/507e92bc6eb96c6646801c23695fd698/0128867905v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/8c/cd8c3ca788be29055f3af26645fa0262/0128810840v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/59/4059f2264fa9693e048ee11050839486/0128700610v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/74/07746815a405db2865052931aa3b9655/0129103565v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/05/11/05119b92ebfd03919d063b254eec1b27/0129056177v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/5d/9b5db33353f3e5a256e2f634ddc349c7/0129333056v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/e1/0ae1b7a9cc45bf10ebcbce27be707eda/0129230371v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f4/e9/f4e9eabb65e0b34fe9911620718ea8e2/0129055594v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ba/7b/ba7bc9220708dc4bd16b8c815db267c2/0128938301v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/ca/f9ca9cace88200a5ec0946f193264963/0129209504v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/61/2f61dd20be68049fa2320a2e5aa860d7/0123789183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c5/49/c54973f28495dada1c7605f913717341/0121533734v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/8f/948f81f46645691d1d90152ef605a0ae/0120806008v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/04/3d/043d3f95c300d98d7188d2c2f0673aa5/0129365083v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/9e/0b9e9ae6c55036cf35f97cd4ffca9d27/0129363249v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3e/fb/3efbcc73e59a0c19de0676cf569c6f28/0129201505v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/59/9e59861a06c0d20831e0d7d5191188ed/0129056166v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/3e/4a3ee5cd13d05629db9d3e88aa22ff01/0129103256v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/b4/6bb456c148f06af9d65155da63665c22/0129102929v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4d/f34d32adcd63bdf5332e4d57ae75611a/0128850501v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7c/a2/7ca2adf016cad8d1de510c4df0ff57bc/0128810813v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/57/9c/579c8e2bcff2e800a19fcb0926e574fa/0129056117v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/5f/4a5fd6bde5784db58812f15386c2126f/0126112832v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/3c/873c56a315b598e5491cef38d9ef72f1/0123364440v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/9c/6b9cab1e262f77caed8179ed3dc29807/0129104421v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/a3/39a32d830d6bb6e4471c79e537c5ca52/chimei-ecologue-frosch-6000x3373v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/29/2b297a2773f13d3017fc6d49424a57b1/0127570680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/fd/07fd8752b8d884ee69baba1b2207d82d/0129373572v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/13/ec/13ece74e59d459301ea38becf80c9706/0129200881v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fe/9b/fe9b79ee842142ff26180132de72b2d5/0129103360v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/7e/2a7e5ced0986e88a6c24123fba954dee/0128871141v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/66/0e/660e93698db24/hasco-logo-or-b50.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/125700/125705/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/118400/118496/65.jpg)

:quality(80)/p7i.vogel.de/wcms/70/62/7062559d37e7a114838fc5b1ffe6b0e9/0123522868v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/36/9e361b748295dc8c623857b045e08cbc/0126109259v1.jpeg)