Related Vendors

Room for about 1,000 electrodes in a 23-metre machining centre

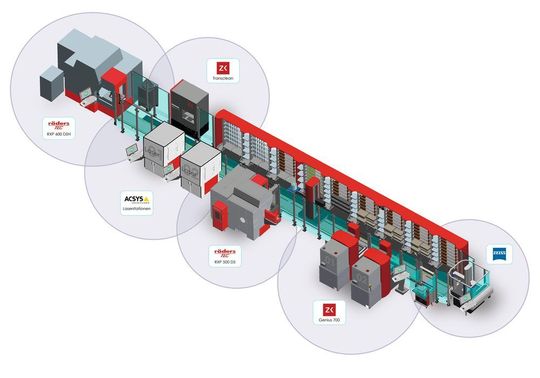

The 23-metre-long machining centre in Walther Wolf’s halls consistc of Laser stations by Acsys, a measuring station by Zeiss, RXP machines by Röders and cleaning stations and EDM systems by Zimmer & Kreim. All these different stations, completed by several metres of storage cupboards, are served by a tower unit with a gripper that is moved electronically. In this automated cell there is room for about 1,000 electrodes at the same time.

All jobs executed by the individual stations are managed with the software by Zimmer & Kreim. This software is one of the significant advantages of the automated cell. The job manager handles offset data, co-ordinates the different processes and collects data around the stored and machined electrodes.

Dorlöchter is particularly happy about the usability of the software. According to him, Zimmer & Kreim's updates are also a great help. Due to them, the machining cell works faster and more efficient today than it did when he first installed it. Additionally, the software has an interface function that allows operators and users to implement their own programs. Moreover, Dorlöchter is very glad about the support of Zimmer & Kreim. “If there were problems, they were settled very quickly and efficiently in co-operation with Zimmer & Kreim,” he says.

The open structure of Zimmer & Kreim allows Dorlöchter and his company to implement processes or optimisation measures that are not available on the market. For the company's manager, this is an incomparable advantage, as every company has its own needs and its own optimisation potential. It is Dorlöchter’s goal to take full advantage of the interface. In past years, he was able to realise several projects that were only possible because it is so easy to combine own innovations with Zimmer & Kreim’s job manager.

:quality(80)/images.vogel.de/vogelonline/bdb/1235400/1235407/original.jpg)

Tech Focus

Complex, fast and fully automated: The art of wire erosion

Automation allows for high utilisation even at night

One thing that has changed since the new cell was implemented is that many tasks that had to be monitored before can now be carried out at night. Things that take up a lot of time therefore do not demand precious working hours. The measuring unit, for example, primarily works at night time without the necessity for an operator being present.

For further improvements, Dorlöchter had several cameras installed. One camera is attached to the tower unit and another camera to the measuring station. That way, the manager or any other operator can check whether everything is running according to plan.

The night-time operation is only one result of Dorlöchter's automation project. All in all, the changes have lead to working more time-efficiently. Staff working time was tremendously reduced to two and a half minutes per electrode. Before implementation, the same work took up more than eleven minutes of working time. All together, there was a strong decrease in the resting time of every electrode. For the company, this means that the machines are working with a higher workload.

“Vacancy can't happen,” says Dorlöchter. Automation for him led to an increase in not only occupancy but consequently to better planning predictability. One reason is that the job-manager software monitors all electrodes, which prevents breaks in processing. At the same time, this monitoring provides detailed projections about machining times. This allows the company to plan ahead and therefore prevent vacancies.

(ID:44620088)

:quality(80)/p7i.vogel.de/wcms/8d/b7/8db71c3fe25cd48399bfd8faaa5e90f7/0129228188v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/44/fc4431baf22faf49f91d695e7725b0de/0129227575v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/49/58/4958084fe5c4ed0a7758f7cfb3051e92/0128854986v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/39/ad3982b17d8034c9134821a24e023d12/0128991046v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/34/2f344c97b0e4a9613850f3bb3b519101/0129337496v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/8c/528c3c99265c6d8951e6bb1dcf4ed7c2/0129224981v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/28/95/28952358db60b91461ebfda8196fad46/0129221819v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d0/bd/d0bd3f70a8063a08274ed663509a1053/0129219028v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5d/3c/5d3cd553a019b4033e441e61f98b23d6/0129229293v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/82/e7/82e72d20cefdef73713b584312be57d0/0129209599v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/76/5276fd0bc681a34a30c4d7dc0ac4784c/0129107063v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d6/f8/d6f8f7b5bc0b08eb7357806e4b4d6df3/0128993006v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ae/7c/ae7cfa25bd4cbdee97cf91514a80a569/0129333424v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/50/7e/507e92bc6eb96c6646801c23695fd698/0128867905v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/8c/cd8c3ca788be29055f3af26645fa0262/0128810840v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/59/4059f2264fa9693e048ee11050839486/0128700610v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/74/07746815a405db2865052931aa3b9655/0129103565v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/05/11/05119b92ebfd03919d063b254eec1b27/0129056177v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/5d/9b5db33353f3e5a256e2f634ddc349c7/0129333056v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/e1/0ae1b7a9cc45bf10ebcbce27be707eda/0129230371v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f4/e9/f4e9eabb65e0b34fe9911620718ea8e2/0129055594v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ba/7b/ba7bc9220708dc4bd16b8c815db267c2/0128938301v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/ca/f9ca9cace88200a5ec0946f193264963/0129209504v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/61/2f61dd20be68049fa2320a2e5aa860d7/0123789183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c5/49/c54973f28495dada1c7605f913717341/0121533734v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/8f/948f81f46645691d1d90152ef605a0ae/0120806008v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3e/fb/3efbcc73e59a0c19de0676cf569c6f28/0129201505v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/59/9e59861a06c0d20831e0d7d5191188ed/0129056166v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/41/93/4193f3985dc04080399cb574e810a79c/0128985792v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ce/94/ce94bd1d0acf451687549f8e3efdb07a/0128981060v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/3e/4a3ee5cd13d05629db9d3e88aa22ff01/0129103256v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/b4/6bb456c148f06af9d65155da63665c22/0129102929v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4d/f34d32adcd63bdf5332e4d57ae75611a/0128850501v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7c/a2/7ca2adf016cad8d1de510c4df0ff57bc/0128810813v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/57/9c/579c8e2bcff2e800a19fcb0926e574fa/0129056117v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/5f/4a5fd6bde5784db58812f15386c2126f/0126112832v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/3c/873c56a315b598e5491cef38d9ef72f1/0123364440v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/00/2a/002ad74723b737fd6e4729e3434f16ab/0123040413v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/9c/6b9cab1e262f77caed8179ed3dc29807/0129104421v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/a3/39a32d830d6bb6e4471c79e537c5ca52/chimei-ecologue-frosch-6000x3373v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/29/2b297a2773f13d3017fc6d49424a57b1/0127570680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/13/ec/13ece74e59d459301ea38becf80c9706/0129200881v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fe/9b/fe9b79ee842142ff26180132de72b2d5/0129103360v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/7e/2a7e5ced0986e88a6c24123fba954dee/0128871141v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/2a/1d2a6bc382131d8cc1f325617e1dced8/0128870377v1.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/66/0e/660e93698db24/hasco-logo-or-b50.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/74/07746815a405db2865052931aa3b9655/0129103565v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/31/be/31be7345020f07989a330cb397b695c9/0128356094v2.jpeg)