Related Vendors

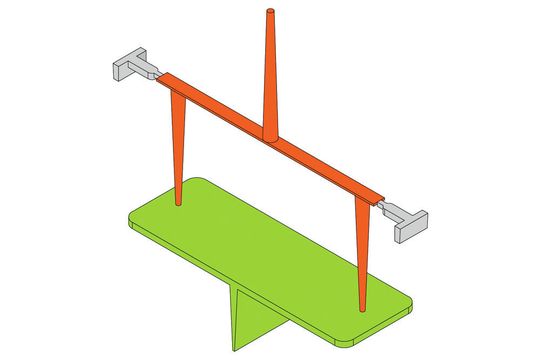

Venting at runner side can also reduce air counter pressure, because the air in the sprue and the cold runner is completely ejected instead of compressed into the cavity. Bernoulli’s principle states that an increase in the speed of a fluid occurs simultaneously with a decrease in pressure. According to this principle, the speed of the air flowing through the cold runner (no counter pressure) toward the valve results in a depression and air suction from cavity to cold runner. The benefits of this can significantly change depending on cold runner and sprue dimensions in relation to the volume of the injected part (see Figure 2).

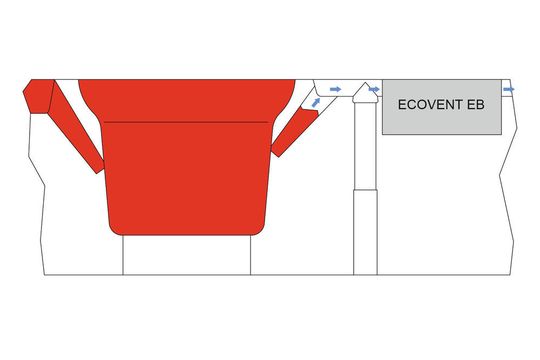

In addition to at runner side, another option for external mould venting is at the last filling point, whereby, while the melt flows forward in the cavity, air and gases flow out through the valve. Thanks to the low air counter pressure in the cavity, injection parameters can be managed in a larger window, optimising injection time, part aesthetics and mechanical characteristics.

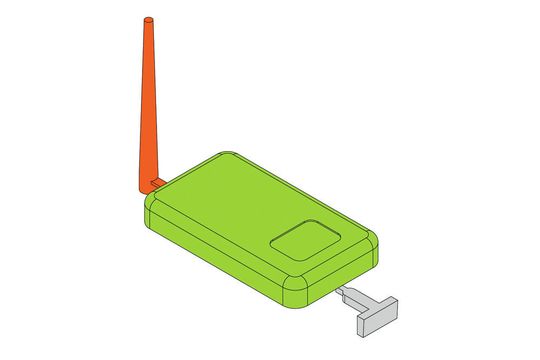

Although external venting generates a small plastic protrusion on the part that must later be removed, a tunnel gate will allow for automatic cutting of this protrusion during part ejection (see Figures 3 and 4).

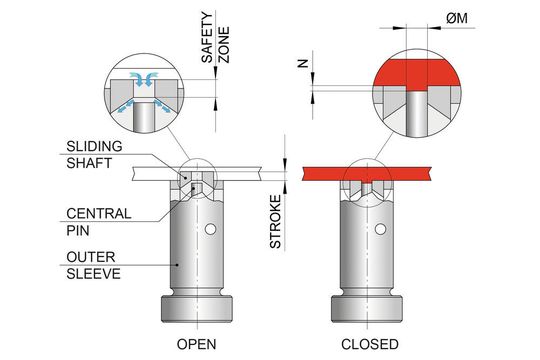

An internal mould-venting valve can be placed inside the cavity of a mould, allowing gas to escape from a venting hole that automatically closes under the pressure of the injected plastic. This type of valve consists of an outer sleeve, a sliding shaft and a central pin that serves to close off the venting hole. During filling, a spring of the appropriate length, wire diameter and preload pushes the sliding shaft forward in open position. While in this open position, air and gases can flow through the central hole and along the wide internal venting channels. When the injected plastic meets the valve, it applies pressure on the shaft surface, compressing the spring and closing the valve. While in closed position, the central pin seals off the venting hole, ensuring the plastic does not fill the valve. The proper working of the valve is guaranteed by accurate sizing of the venting hole, the safety zone and spring preload. These parameters allow the valve to close before the melt fills the wide venting channels (see Figure 5).

The design of this type of valve requires the sliding shaft to stick into the cavity while the valve is in open position. This guarantees open venting channels. The central shaft moves up and down for a defined stroke to suit plastic part wall thickness. The shorter the stroke, the longer the plastic protrusion on the part (see “N” reference in Figure 6). This shaft stroke also can affect the filling pattern of the cavity. The thinner the plastic part, the shorter the stroke should be. Part thickness and aesthetic requirements also determine the necessary overall valve size.

Ermanno Balzi is present at Moulding Expo: Hall 4, Booth B76.

(ID:44611135)

:quality(80)/p7i.vogel.de/wcms/44/a5/44a595ea8cbd7ca3de26d2fa0d44b5f2/0128811358v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7d/d5/7dd5712eb281b2c1301aee6711f091c3/0128808096v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/21/69/21691745c07c5c5d82e595ec4774b9aa/0128682698v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a7/85/a785365350a3e947497f00f47b82b039/0128627886v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d0/18/d01856df41be0149042e9f1977f8b028/0128664298v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/32/39/323954fb2abc56983e0cd7cb3560246c/0128664485v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/aa/8f/aa8f4f950cc0e190751689dba69eea01/0128565967v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/8c/408cd551b8091b69cfed78e197a5a476/0128563423v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/15/4f15c3bb14bab92080bf996709a83645/0128563218v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/42/31/42313bd220cdcb8af7fb8e067a83d50c/0128557097v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/8a/70/8a70819e022170d9daef7c0ccec1821d/0128495766v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/b4/adb4bb0edc1a6f8fd034c6a37e175e9d/0128356211v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/50/7e/507e92bc6eb96c6646801c23695fd698/0128867905v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/8c/cd8c3ca788be29055f3af26645fa0262/0128810840v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/59/4059f2264fa9693e048ee11050839486/0128700610v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/c2/e1/c2e1b679261a399bf6269dc373c102fa/0127678469v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/d2/51d230163a0fef3d986cf8b3f30951f1/0128682701v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/22/0e/220efd3f7f8f358b48a574bf0eec4ea7/0128664282v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/36/b6/36b69f3d3be92a1b0d1a1caaec3aaeb1/0128633689v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7c/67/7c67ad526570b346eb2a76df58c0f4ba/0128631376v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/ac/24ac3a9f884a5e5b306956e31a9b4deb/0128861196v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/77/87/77871c4c292c70617d166654c0d1c163/0128700299v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/73/be/73bec93ee96729e2c1e4dc97ed4a8901/0128496648v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/78/86/78865609f51a72235f82b1175fef3783/0128355985v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/61/2f61dd20be68049fa2320a2e5aa860d7/0123789183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c5/49/c54973f28495dada1c7605f913717341/0121533734v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/8f/948f81f46645691d1d90152ef605a0ae/0120806008v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a7/71/a77110eca4700757403af4ec15407500/0120450681v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/4a/5a4afa231d7e866a871940b6e3cbf13f/0128810805v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/89/04/8904ab16b77655a483945ae9a61551ac/0128635010v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/63/b9/63b93a7420eba16e25feaacb80f8e82c/0128496384v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/31/be/31be7345020f07989a330cb397b695c9/0128356094v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4d/f34d32adcd63bdf5332e4d57ae75611a/0128850501v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7c/a2/7ca2adf016cad8d1de510c4df0ff57bc/0128810813v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/49/47/4947b843c01af2530f6ee7b1ead12615/0128496364v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/05/65/056575417733c00d05e7a79c19515c66/0128060803v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/5f/4a5fd6bde5784db58812f15386c2126f/0126112832v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/3c/873c56a315b598e5491cef38d9ef72f1/0123364440v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/00/2a/002ad74723b737fd6e4729e3434f16ab/0123040413v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/a6/cca6a2e5fde9c86e0322d88849afaf65/0120949147v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/a3/39a32d830d6bb6e4471c79e537c5ca52/chimei-ecologue-frosch-6000x3373v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/29/2b297a2773f13d3017fc6d49424a57b1/0127570680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/cf/47/cf47e0f2838a93620ef614c97ce46a02/0126485311v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f1/b0/f1b03ea58663a165eef76c8353826097/0126198690v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/7e/2a7e5ced0986e88a6c24123fba954dee/0128871141v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/2a/1d2a6bc382131d8cc1f325617e1dced8/0128870377v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/c9/dec91a3f4969c194567937304290d836/0128682667v1.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/66/0e/660e93698db24/hasco-logo-or-b50.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/69/67/69677c0bae65d/pfg-logo.png)

:quality(80)/p7i.vogel.de/wcms/19/46/1946128e219613a59adb20ce3dbf1386/0127812088v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/70/62/7062559d37e7a114838fc5b1ffe6b0e9/0123522868v1.jpeg)