Related Vendors

Alternative Venting Solutions

An overflow system (an area connected to the cavity via a channel) can be created by machining an exit gate that connects the cavity’s last filling point with a cold runner that ends in a venting area with a vent measuring about 0.1 mm. A groove is then machined around the vent to collect the gases and allow them to exit from the mould. During the filling process, air can then flow through the gate, cold runner, vent and gas-venting groove. Plastic freezes in the vent and is removed after every shot.

Rheology (filling analyses) or trial and error can be used to determine proper vent size in this type of system. The designer can start with a vent height of 0.1 mm and length of 10 mm, and adjust as needed. The main benefit of an overflow system is the ability to overcome vent limits. Flash in the overflow area should not be a problem as long as it will be cut from the cavity after every shot.

:quality(80)/images.vogel.de/vogelonline/bdb/1227200/1227231/original.jpg)

ETMM Magazine

May 2017 product gallery

Limitations of an overflow system include extra material being wasted after every shot, overflow cutting operation and additional space requirements. Also, the position of the venting gate needs to be at a mould parting line, and this does not solve air-trap issues.

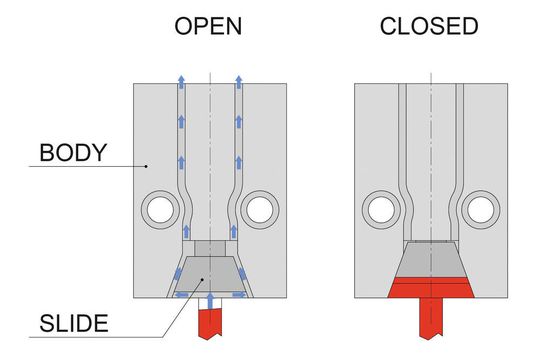

Dynamic (as opposed to static) venting valves are an alternative venting solution that can be either external (connected via a channel or on the cold runner, if the mould has one) or internal to the mould cavity. They are designed to allow the air and resin gases to rapidly leave the cavity via a venting channel that is a few square millimeters — large enough to overcome the geometrical limits of standard venting grooves. The external mould-venting valve consists of a body that houses a guide for a slide.

Both the body and the guide are designed to guarantee a conical closure when the sliding element moves. A spring keeps the slide in an open position to create an increased venting volume for the mould cavity. The body also contains wide venting channels connected to the venting area between the body and slide (Figure 1b).

The venting valve is connected to the cavity or cold runner by a groove that allows the gas to flow from the mould cavity to the valve. When the injected plastic reaches the vent, it applies pressure on the slide, compressing the spring, causing it to perform the conical closure and preventing the plastic from flowing into the valve. The venting grooves on the valve body are connected to the open venting space by machined channels. These channels must be as straight as possible to maximise the venting performance of the valve. The valve itself can be located in different positions in the mould to achieve various benefits and mould performance.

The main benefit of external mould venting at runner side is the ability to vent the gases during moulding at the subrunner. Gases are usually pushed into the cavity with the plastic material, and with an external venting approach, the gases naturally flow where the drag is lower. For example, resistance to the flow at the end of the cold runner is very low compared to the resistance inside the cavity, where the number of vents is limited.

(ID:44611135)

:quality(80)/p7i.vogel.de/wcms/44/a5/44a595ea8cbd7ca3de26d2fa0d44b5f2/0128811358v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7d/d5/7dd5712eb281b2c1301aee6711f091c3/0128808096v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/21/69/21691745c07c5c5d82e595ec4774b9aa/0128682698v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a7/85/a785365350a3e947497f00f47b82b039/0128627886v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d0/18/d01856df41be0149042e9f1977f8b028/0128664298v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/32/39/323954fb2abc56983e0cd7cb3560246c/0128664485v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/aa/8f/aa8f4f950cc0e190751689dba69eea01/0128565967v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/8c/408cd551b8091b69cfed78e197a5a476/0128563423v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/15/4f15c3bb14bab92080bf996709a83645/0128563218v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/42/31/42313bd220cdcb8af7fb8e067a83d50c/0128557097v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/8a/70/8a70819e022170d9daef7c0ccec1821d/0128495766v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/b4/adb4bb0edc1a6f8fd034c6a37e175e9d/0128356211v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/50/7e/507e92bc6eb96c6646801c23695fd698/0128867905v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/8c/cd8c3ca788be29055f3af26645fa0262/0128810840v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/59/4059f2264fa9693e048ee11050839486/0128700610v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/c2/e1/c2e1b679261a399bf6269dc373c102fa/0127678469v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/51/d2/51d230163a0fef3d986cf8b3f30951f1/0128682701v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/22/0e/220efd3f7f8f358b48a574bf0eec4ea7/0128664282v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/36/b6/36b69f3d3be92a1b0d1a1caaec3aaeb1/0128633689v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7c/67/7c67ad526570b346eb2a76df58c0f4ba/0128631376v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/ac/24ac3a9f884a5e5b306956e31a9b4deb/0128861196v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/77/87/77871c4c292c70617d166654c0d1c163/0128700299v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/73/be/73bec93ee96729e2c1e4dc97ed4a8901/0128496648v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/78/86/78865609f51a72235f82b1175fef3783/0128355985v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/61/2f61dd20be68049fa2320a2e5aa860d7/0123789183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c5/49/c54973f28495dada1c7605f913717341/0121533734v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/8f/948f81f46645691d1d90152ef605a0ae/0120806008v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a7/71/a77110eca4700757403af4ec15407500/0120450681v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/5a/4a/5a4afa231d7e866a871940b6e3cbf13f/0128810805v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/89/04/8904ab16b77655a483945ae9a61551ac/0128635010v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/63/b9/63b93a7420eba16e25feaacb80f8e82c/0128496384v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/31/be/31be7345020f07989a330cb397b695c9/0128356094v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4d/f34d32adcd63bdf5332e4d57ae75611a/0128850501v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7c/a2/7ca2adf016cad8d1de510c4df0ff57bc/0128810813v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/49/47/4947b843c01af2530f6ee7b1ead12615/0128496364v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/05/65/056575417733c00d05e7a79c19515c66/0128060803v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/5f/4a5fd6bde5784db58812f15386c2126f/0126112832v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/3c/873c56a315b598e5491cef38d9ef72f1/0123364440v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/00/2a/002ad74723b737fd6e4729e3434f16ab/0123040413v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/cc/a6/cca6a2e5fde9c86e0322d88849afaf65/0120949147v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/a3/39a32d830d6bb6e4471c79e537c5ca52/chimei-ecologue-frosch-6000x3373v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/29/2b297a2773f13d3017fc6d49424a57b1/0127570680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/cf/47/cf47e0f2838a93620ef614c97ce46a02/0126485311v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f1/b0/f1b03ea58663a165eef76c8353826097/0126198690v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/7e/2a7e5ced0986e88a6c24123fba954dee/0128871141v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/2a/1d2a6bc382131d8cc1f325617e1dced8/0128870377v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/de/c9/dec91a3f4969c194567937304290d836/0128682667v1.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/66/0e/660e93698db24/hasco-logo-or-b50.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/69/67/69677c0bae65d/pfg-logo.png)

:quality(80)/p7i.vogel.de/wcms/19/46/1946128e219613a59adb20ce3dbf1386/0127812088v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/70/62/7062559d37e7a114838fc5b1ffe6b0e9/0123522868v1.jpeg)