Related Vendors

Insertion of steel rods and extrusion coating in one production phase

Volker Scheffels explains: “Our customers' considerations regarding individual components relate, on the one hand, to their technical and economic features, and, on the other hand, to their optimal usage properties on the part of the end-user. We frequently come into play during the production engineering process. Our knowledge and experience in procedure and production technology help us to find the correct solutions for implementing customers' ideas in completed modules. If you currently want to convert complex plastic components into even more complex modules, then it is not enough to only know about plastic processing technology. They must also possess a deep knowledge of diverse production technology. They must not only master their own production processes, but they must also know their customers' installation processes exactly and take them into account. We have not only mastered our own on-site injection moulding and the most diverse production process techniques possible, but also gluing processes, ultrasonic welding, printing technology, such as screen printing and pad printing, as well as plasma treatment for manufacturing hydrophilic plastic surfaces. All in all, all knowledge that is not obvious to an injection moulder.”

There are many outstanding examples on-site at EKT that attest to Scheffels' statement. For example, a Miele idea consisted of improving the usage of a crockery-cutlery drawer for the consumer by means of higher variability and adjustability for the individual cutlery drawer segments. Simultaneously, the production costs should be reduced by the component's rigidity no longer being substituted by bogie frames, but by strengthened plastic components.

For a dishwasher temperature of up to 90° C and with a possible cutlery drawer weight of several kilogrammes, the purely plastic component would no longer be stable. For this reason, EKT is developing new production technology, by means of which a large number of steel rods are inserted and extrusion-coated as part of one production phase. Consequently, it was possible to do the customer requirement for variability justice and also reduce component costs. Here, the particular challenge was the fully automatic conversion when separating the steel bars into different diameters with subsequent 100% extrusion-coating. Any possible distortions that may arise as a result extrusion-coating the stainless-steel bar have been calculated in advance and taken into account as part of the design of the tools with the result that, as part of this process, the tool contains defined “sloping”, meaning that a perfect cutlery component is always produced after the cooling process.

:quality(80)/images.vogel.de/vogelonline/bdb/1275200/1275283/original.jpg)

Männer

Multi-component production using side valve gate nozzle

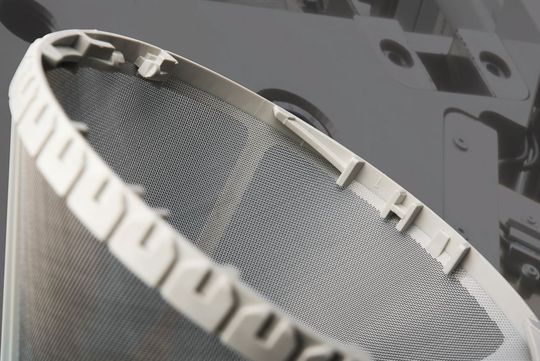

EKT uses an additional component to demonstrate how a funnel-shaped micro-fine filter screen for dishwashers, which was partially constructed by hand by a sub-supplier, can today be completely manufactured in a single injection-moulding processing step. The specific technical challenge for this component consists of mounting the fine-pore micro-filter tissue made of stainless steel, which is present as a two-dimensional blank in plano in an extraction device, over the course of a 22-second process cycle in a reliable manner, inserting it into the injection-moulding machine, moulding it there into a funnel shape and subsequently extrusion-coating it.

The safe and trouble-free mounting of the micro-filter blank for the extraction device does represent something of a technical high-standard requirement, since screen tissue can only be held with a clamping device with a huge amount of difficulty. In order to guarantee separate mounting with the screen being securely grasped, EKT has developed a mounting device, with which the micro-fine filter screen is both attached and simultaneously lifted; separation is assured, meaning that the screen can be safely inserted into the injection-moulding machine for the additional conversion process.

(ID:44869787)

:quality(80)/p7i.vogel.de/wcms/8d/b7/8db71c3fe25cd48399bfd8faaa5e90f7/0129228188v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/44/fc4431baf22faf49f91d695e7725b0de/0129227575v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/49/58/4958084fe5c4ed0a7758f7cfb3051e92/0128854986v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/39/ad3982b17d8034c9134821a24e023d12/0128991046v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/34/2f344c97b0e4a9613850f3bb3b519101/0129337496v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/8c/528c3c99265c6d8951e6bb1dcf4ed7c2/0129224981v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/28/95/28952358db60b91461ebfda8196fad46/0129221819v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d0/bd/d0bd3f70a8063a08274ed663509a1053/0129219028v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b7/e0/b7e0832ad0be13fb559a7028f2ef02c7/0129386806v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5d/3c/5d3cd553a019b4033e441e61f98b23d6/0129229293v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/82/e7/82e72d20cefdef73713b584312be57d0/0129209599v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/76/5276fd0bc681a34a30c4d7dc0ac4784c/0129107063v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ae/7c/ae7cfa25bd4cbdee97cf91514a80a569/0129333424v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/50/7e/507e92bc6eb96c6646801c23695fd698/0128867905v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/8c/cd8c3ca788be29055f3af26645fa0262/0128810840v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/59/4059f2264fa9693e048ee11050839486/0128700610v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/74/07746815a405db2865052931aa3b9655/0129103565v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/05/11/05119b92ebfd03919d063b254eec1b27/0129056177v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/5d/9b5db33353f3e5a256e2f634ddc349c7/0129333056v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/e1/0ae1b7a9cc45bf10ebcbce27be707eda/0129230371v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f4/e9/f4e9eabb65e0b34fe9911620718ea8e2/0129055594v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ba/7b/ba7bc9220708dc4bd16b8c815db267c2/0128938301v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/ca/f9ca9cace88200a5ec0946f193264963/0129209504v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/61/2f61dd20be68049fa2320a2e5aa860d7/0123789183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c5/49/c54973f28495dada1c7605f913717341/0121533734v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/8f/948f81f46645691d1d90152ef605a0ae/0120806008v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/04/3d/043d3f95c300d98d7188d2c2f0673aa5/0129365083v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/9e/0b9e9ae6c55036cf35f97cd4ffca9d27/0129363249v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3e/fb/3efbcc73e59a0c19de0676cf569c6f28/0129201505v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/59/9e59861a06c0d20831e0d7d5191188ed/0129056166v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/3e/4a3ee5cd13d05629db9d3e88aa22ff01/0129103256v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/b4/6bb456c148f06af9d65155da63665c22/0129102929v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4d/f34d32adcd63bdf5332e4d57ae75611a/0128850501v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7c/a2/7ca2adf016cad8d1de510c4df0ff57bc/0128810813v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/57/9c/579c8e2bcff2e800a19fcb0926e574fa/0129056117v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/5f/4a5fd6bde5784db58812f15386c2126f/0126112832v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/3c/873c56a315b598e5491cef38d9ef72f1/0123364440v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/9c/6b9cab1e262f77caed8179ed3dc29807/0129104421v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/a3/39a32d830d6bb6e4471c79e537c5ca52/chimei-ecologue-frosch-6000x3373v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/29/2b297a2773f13d3017fc6d49424a57b1/0127570680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/fd/07fd8752b8d884ee69baba1b2207d82d/0129373572v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/13/ec/13ece74e59d459301ea38becf80c9706/0129200881v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fe/9b/fe9b79ee842142ff26180132de72b2d5/0129103360v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/7e/2a7e5ced0986e88a6c24123fba954dee/0128871141v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/66/0e/660e93698db24/hasco-logo-or-b50.jpeg)

:quality(80)/p7i.vogel.de/wcms/70/62/7062559d37e7a114838fc5b1ffe6b0e9/0123522868v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4e/60/4e608f0d2830e31c8705a44d57df23e3/0124618646v1.jpeg)