Styrenic Polymers Styrenics files EU authorisation for mechanically recycled polystyrene as food contact material

Belgium — The value chain initiative to realise the circular economy for styrenic polymers, Styrenics Circular Solutions (SCS), has filed its second application for EU authorisation of mechanically recycled polystyrene (rPS) as food contact material. SCS has now already two submissions to be assessed by the European Food Safety Authority (Efsa).

Related Vendors

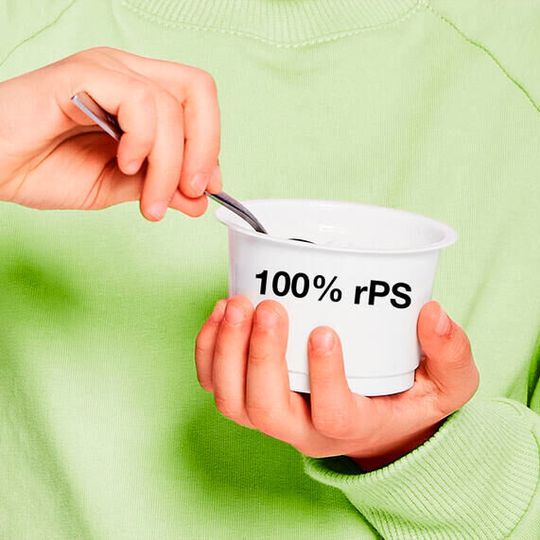

The mechanically recycled polystyrene products developed Styrenics, cover multiple end-consumer applications, including yoghurt pots, hot and cold beverage containers and food trays. However, they are based on two different super-cleaning technologies as part of PET-like food contact mechanical recycling processes. The rPS content in end-consumer applications can range up to 100 percent.

The scientific dossier by Fraunhofer IVV for this second application follows several challenge tests performed with the super-cleaning technology of plastic recycling machine manufacturer Gneuss. According to the dossier, the process consistently delivered a recycled polymer with excellent purity, based on post-consumer food packaging waste. The results were delivered by Gneuss’ Multi Rotation System (MRS) jump extrusion process that enables highly efficient super-cleaning based on high vacuum, high surface and melt temperature. Fraunhofer IVV confirmed the lent cleaning efficiency demonstrated in the challenge tests. This technology already has an established track record in Japan, where Gneuss have provided FDA approved super-cleaning for food contact mechanical recycling of food trays since 2017.

PET-like high purity mechanical recycling is one of the multiple plastic-to-plastic recycling options available for polystyrene next to dissolution and depolymerisation. PS benefits from the same inherent low-diffusion characteristic as PET, which enables mechanical recycling to food grade standards. ‘

(ID:48021020)

:quality(80)/p7i.vogel.de/wcms/d2/63/d26376330f084c718f9ab83fc66eb39f/0129319680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/a9/4fa94db21a092a12fdb0822e3d5c8150/0129504798v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/8d/b7/8db71c3fe25cd48399bfd8faaa5e90f7/0129228188v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/44/fc4431baf22faf49f91d695e7725b0de/0129227575v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ba/ea/baea897f2d161c46f0872c77cd26fb6b/0129039787v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a6/06/a606d5e06236baca21d7f53019dedf42/0129504701v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/a8/0ba81aaff9b06473404eafd31bfbfe06/0129451471v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/34/2f344c97b0e4a9613850f3bb3b519101/0129337496v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/63/53/6353c75a9072fc20846b40065c12f724/0129533055v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b7/e0/b7e0832ad0be13fb559a7028f2ef02c7/0129386806v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5d/3c/5d3cd553a019b4033e441e61f98b23d6/0129229293v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/82/e7/82e72d20cefdef73713b584312be57d0/0129209599v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/84/24844705e911d0231a551255ab3a7ee7/0129505503v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ae/7c/ae7cfa25bd4cbdee97cf91514a80a569/0129333424v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/50/7e/507e92bc6eb96c6646801c23695fd698/0128867905v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/8c/cd8c3ca788be29055f3af26645fa0262/0128810840v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/c8/43/c843d8084b4db01b20506a3773a8e56d/0129505472v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/8c/528c3c99265c6d8951e6bb1dcf4ed7c2/0129224981v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/28/95/28952358db60b91461ebfda8196fad46/0129221819v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/96/16/9616c2fc580d720e8b3f91bbffcc5a01/0129504787v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/5d/9b5db33353f3e5a256e2f634ddc349c7/0129333056v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/e1/0ae1b7a9cc45bf10ebcbce27be707eda/0129230371v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f4/e9/f4e9eabb65e0b34fe9911620718ea8e2/0129055594v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/ca/f9ca9cace88200a5ec0946f193264963/0129209504v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/61/2f61dd20be68049fa2320a2e5aa860d7/0123789183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c5/49/c54973f28495dada1c7605f913717341/0121533734v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/8f/948f81f46645691d1d90152ef605a0ae/0120806008v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/88/a2/88a2be18834640f6e34db6bcaa98da06/0129504771v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/04/3d/043d3f95c300d98d7188d2c2f0673aa5/0129365083v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/9e/0b9e9ae6c55036cf35f97cd4ffca9d27/0129363249v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/3e/4a3ee5cd13d05629db9d3e88aa22ff01/0129103256v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/b4/6bb456c148f06af9d65155da63665c22/0129102929v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4d/f34d32adcd63bdf5332e4d57ae75611a/0128850501v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7c/a2/7ca2adf016cad8d1de510c4df0ff57bc/0128810813v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/57/9c/579c8e2bcff2e800a19fcb0926e574fa/0129056117v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/5f/4a5fd6bde5784db58812f15386c2126f/0126112832v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/3c/873c56a315b598e5491cef38d9ef72f1/0123364440v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/9c/6b9cab1e262f77caed8179ed3dc29807/0129104421v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/49/58/4958084fe5c4ed0a7758f7cfb3051e92/0128854986v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/a3/39a32d830d6bb6e4471c79e537c5ca52/chimei-ecologue-frosch-6000x3373v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/29/2b297a2773f13d3017fc6d49424a57b1/0127570680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/fd/07fd8752b8d884ee69baba1b2207d82d/0129373572v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/13/ec/13ece74e59d459301ea38becf80c9706/0129200881v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fe/9b/fe9b79ee842142ff26180132de72b2d5/0129103360v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/7e/2a7e5ced0986e88a6c24123fba954dee/0128871141v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/66/0e/660e93698db24/hasco-logo-or-b50.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/26200/26226/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/67/d9/67d95fe309f52/logo-300-169-rgb.jpeg)

:quality(80)/p7i.vogel.de/wcms/25/87/25875e8f687cad30d301a3cf3396c289/0126083788v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/bf/f9/bff9df3f2ddeb364ad73a4628d33aac5/0123640603v2.jpeg)