Related Vendors

Cambrio: Increase productivity with Gibbscam

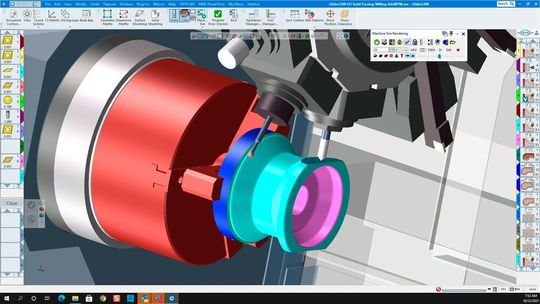

CAD/CAM specialist Cambrio introduces the new version Gibbscam 2022. As Nick Spurrett, Vice President of Gibbscam, explains, the focus of the latest developments is on user productivity.

Gibbscam 2022 includes a number of CAD enhancements for solid and surface modelling. Among other things, it is now possible to extrude multiple solids with taper, create surfaces as connected solids directly from a closed 2D geometry and create trimmed planar surfaces in the geometry depth instead of the CS plane.

Efficient processing and machining

Among the many CAM additions in Gibbscam 2022 are a number of usability enhancements, such as automatic pre-drilling of multiple shapes and advanced control of profiling toolpath start and end points. Lathe operators can now omit radius moves on outside corners for critical diameters and reduced G-code files.

Volumill has also been improved and is now up to 60 percent faster at calculating rest milling operations for complex geometries. In addition, it is now possible for the user to control the starting point to aid chip removal and reduce rapid movements for deeper pockets.

Improvements in 5-axis machining include a new rotary machining strategy that efficiently cuts parts with cylindrical or conical bottoms. Tool control includes off-centre roughing and forward or backward tool tip attachment with automatic corner offset. In 5-axis deburring, it is now possible to create multiple cuts to produce a chamfer or fillet on an edge beyond the traditional edge break. Cylindrical or conical tools can also be used for chamfering by selecting a specific contact point to obtain a straight tool cut. Toolpath quality has also been improved for 5-axis geodesic operations in areas where multiple surface normal instances control the toolpath.

Save time during simulation

In a collision-prone environment such as milling/turning or tombstone machining, simulation is a key component. That's why Gibbscam 2022 aims to provide a number of time-saving enhancements. Among other things, Hide Multipart Cutting can be disabled in all simulation modes to reduce verification time depending on the number of components to be machined. The usage of 3D material used only for blank generation on multi-spindle machines can improve the simulation of MTM configurations by up to 25 times, according to the manufacturer. Users can now start the simulation in the middle of an MTM or Swiss programme with multiple parts.

Multiple kinematic configurations of a CNC machine are now supported within a single post-processor package. This enhanced flexibility supports machines that can be configured in different ways, such as a 3-axis machine with or without a removable rotary table. This technology can also be extended to more complex sliding headstock configurations to support different parts or tooling arrangements - one part, one post-processor, one machine simulation model.

(ID:47957793)

:quality(80)/p7i.vogel.de/wcms/8d/b7/8db71c3fe25cd48399bfd8faaa5e90f7/0129228188v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/44/fc4431baf22faf49f91d695e7725b0de/0129227575v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/49/58/4958084fe5c4ed0a7758f7cfb3051e92/0128854986v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/39/ad3982b17d8034c9134821a24e023d12/0128991046v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/8c/528c3c99265c6d8951e6bb1dcf4ed7c2/0129224981v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/28/95/28952358db60b91461ebfda8196fad46/0129221819v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d0/bd/d0bd3f70a8063a08274ed663509a1053/0129219028v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a4/ca/a4ca8936e35f5a4ea31c468fd57e497e/0128938520v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5d/3c/5d3cd553a019b4033e441e61f98b23d6/0129229293v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/82/e7/82e72d20cefdef73713b584312be57d0/0129209599v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/76/5276fd0bc681a34a30c4d7dc0ac4784c/0129107063v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d6/f8/d6f8f7b5bc0b08eb7357806e4b4d6df3/0128993006v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/50/7e/507e92bc6eb96c6646801c23695fd698/0128867905v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/8c/cd8c3ca788be29055f3af26645fa0262/0128810840v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/40/59/4059f2264fa9693e048ee11050839486/0128700610v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/c2/e1/c2e1b679261a399bf6269dc373c102fa/0127678469v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/74/07746815a405db2865052931aa3b9655/0129103565v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/05/11/05119b92ebfd03919d063b254eec1b27/0129056177v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/5d/9b5db33353f3e5a256e2f634ddc349c7/0129333056v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/e1/0ae1b7a9cc45bf10ebcbce27be707eda/0129230371v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f4/e9/f4e9eabb65e0b34fe9911620718ea8e2/0129055594v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ba/7b/ba7bc9220708dc4bd16b8c815db267c2/0128938301v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/ca/f9ca9cace88200a5ec0946f193264963/0129209504v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/61/2f61dd20be68049fa2320a2e5aa860d7/0123789183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c5/49/c54973f28495dada1c7605f913717341/0121533734v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/8f/948f81f46645691d1d90152ef605a0ae/0120806008v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3e/fb/3efbcc73e59a0c19de0676cf569c6f28/0129201505v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/59/9e59861a06c0d20831e0d7d5191188ed/0129056166v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/41/93/4193f3985dc04080399cb574e810a79c/0128985792v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ce/94/ce94bd1d0acf451687549f8e3efdb07a/0128981060v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/3e/4a3ee5cd13d05629db9d3e88aa22ff01/0129103256v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/b4/6bb456c148f06af9d65155da63665c22/0129102929v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4d/f34d32adcd63bdf5332e4d57ae75611a/0128850501v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7c/a2/7ca2adf016cad8d1de510c4df0ff57bc/0128810813v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/57/9c/579c8e2bcff2e800a19fcb0926e574fa/0129056117v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/5f/4a5fd6bde5784db58812f15386c2126f/0126112832v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/3c/873c56a315b598e5491cef38d9ef72f1/0123364440v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/00/2a/002ad74723b737fd6e4729e3434f16ab/0123040413v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/9c/6b9cab1e262f77caed8179ed3dc29807/0129104421v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/a3/39a32d830d6bb6e4471c79e537c5ca52/chimei-ecologue-frosch-6000x3373v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/29/2b297a2773f13d3017fc6d49424a57b1/0127570680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/13/ec/13ece74e59d459301ea38becf80c9706/0129200881v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fe/9b/fe9b79ee842142ff26180132de72b2d5/0129103360v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/7e/2a7e5ced0986e88a6c24123fba954dee/0128871141v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/2a/1d2a6bc382131d8cc1f325617e1dced8/0128870377v1.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/66/0e/660e93698db24/hasco-logo-or-b50.jpeg)

:quality(80)/p7i.vogel.de/wcms/fa/3e/fa3e1acc1ea2cd85127b50c82b07e739/0124176255v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f4/e9/f4e9eabb65e0b34fe9911620718ea8e2/0129055594v1.jpeg)