Conserving resources How innovative hot runner technology uses material more efficiently

Plastics are a material with a promising future that takes global megatrends into account. They are also eco-efficient, provided they are properly recycled. The development of a functioning recycling economy for polymer materials is therefore a top issue for Günther Hot Runner Technology.

Related Vendors

Günther Hot Runners has set its focus on resource conservation with innovative solutions. “Since plastic granulates that are not processed do not have to be recycled or destroyed. This already starts with product design and tool construction,” explains Horst-Werner Bremmer, Head of Application Technology Consulting and Sales at Günther.

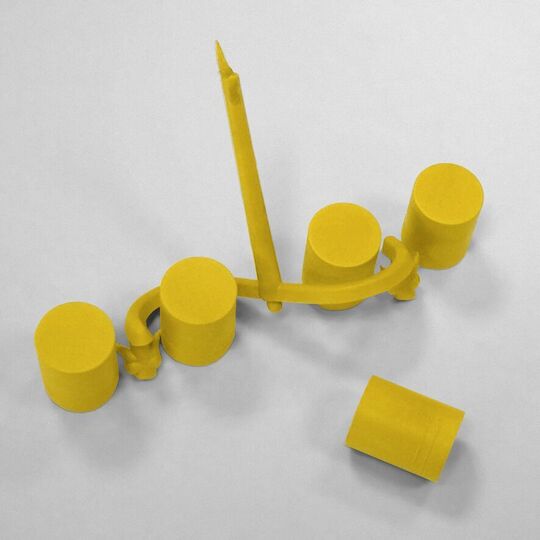

“Many designers shape their products in such a way that, for example, direct gating is often not possible and complex sprue designs are necessary.” As an example, he cites the material savings in the production of a front cap made of LCP, where the article weight was 1.11 g and the sprue weight was 3.15 g. “The sprue weight was 7.59 g,” he says. The shot weight was 7.59 g. After the conversion to a hot runner with valve gate, the shot weight could be reduced to 4.44 g. “The projected number of pieces was 1.5 million parts. Without the use of a hot runner system, 2.8 t of pellets would have been required. By converting to a hot runner with valve gate, 1.2 t of material could be saved,” Horst-Werner Bremmer calculates. Innovative hot runner technology can therefore contribute a lot to the conservation of resources.

(ID:48291503)

:quality(80)/p7i.vogel.de/wcms/d2/63/d26376330f084c718f9ab83fc66eb39f/0129319680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/a9/4fa94db21a092a12fdb0822e3d5c8150/0129504798v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/8d/b7/8db71c3fe25cd48399bfd8faaa5e90f7/0129228188v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/44/fc4431baf22faf49f91d695e7725b0de/0129227575v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ba/ea/baea897f2d161c46f0872c77cd26fb6b/0129039787v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a6/06/a606d5e06236baca21d7f53019dedf42/0129504701v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/a8/0ba81aaff9b06473404eafd31bfbfe06/0129451471v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/34/2f344c97b0e4a9613850f3bb3b519101/0129337496v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/63/53/6353c75a9072fc20846b40065c12f724/0129533055v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b7/e0/b7e0832ad0be13fb559a7028f2ef02c7/0129386806v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5d/3c/5d3cd553a019b4033e441e61f98b23d6/0129229293v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/82/e7/82e72d20cefdef73713b584312be57d0/0129209599v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/84/24844705e911d0231a551255ab3a7ee7/0129505503v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ae/7c/ae7cfa25bd4cbdee97cf91514a80a569/0129333424v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/50/7e/507e92bc6eb96c6646801c23695fd698/0128867905v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/8c/cd8c3ca788be29055f3af26645fa0262/0128810840v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/c8/43/c843d8084b4db01b20506a3773a8e56d/0129505472v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/8c/528c3c99265c6d8951e6bb1dcf4ed7c2/0129224981v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/28/95/28952358db60b91461ebfda8196fad46/0129221819v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/96/16/9616c2fc580d720e8b3f91bbffcc5a01/0129504787v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/5d/9b5db33353f3e5a256e2f634ddc349c7/0129333056v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/e1/0ae1b7a9cc45bf10ebcbce27be707eda/0129230371v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f4/e9/f4e9eabb65e0b34fe9911620718ea8e2/0129055594v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/ca/f9ca9cace88200a5ec0946f193264963/0129209504v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/61/2f61dd20be68049fa2320a2e5aa860d7/0123789183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c5/49/c54973f28495dada1c7605f913717341/0121533734v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/8f/948f81f46645691d1d90152ef605a0ae/0120806008v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/88/a2/88a2be18834640f6e34db6bcaa98da06/0129504771v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/04/3d/043d3f95c300d98d7188d2c2f0673aa5/0129365083v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/9e/0b9e9ae6c55036cf35f97cd4ffca9d27/0129363249v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/3e/4a3ee5cd13d05629db9d3e88aa22ff01/0129103256v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/b4/6bb456c148f06af9d65155da63665c22/0129102929v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4d/f34d32adcd63bdf5332e4d57ae75611a/0128850501v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7c/a2/7ca2adf016cad8d1de510c4df0ff57bc/0128810813v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/57/9c/579c8e2bcff2e800a19fcb0926e574fa/0129056117v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/5f/4a5fd6bde5784db58812f15386c2126f/0126112832v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/3c/873c56a315b598e5491cef38d9ef72f1/0123364440v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/9c/6b9cab1e262f77caed8179ed3dc29807/0129104421v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/49/58/4958084fe5c4ed0a7758f7cfb3051e92/0128854986v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/a3/39a32d830d6bb6e4471c79e537c5ca52/chimei-ecologue-frosch-6000x3373v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/29/2b297a2773f13d3017fc6d49424a57b1/0127570680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/fd/07fd8752b8d884ee69baba1b2207d82d/0129373572v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/13/ec/13ece74e59d459301ea38becf80c9706/0129200881v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fe/9b/fe9b79ee842142ff26180132de72b2d5/0129103360v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/7e/2a7e5ced0986e88a6c24123fba954dee/0128871141v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/66/0e/660e93698db24/hasco-logo-or-b50.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/125700/125705/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/67/d9/67d95fe309f52/logo-300-169-rgb.jpeg)

:quality(80)/p7i.vogel.de/wcms/7a/8f/7a8fd0e2c47a69b277acef4536d5d25b/0126745996v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/22/0b/220bb75660b86b93f2188070cfb3da7b/0125957986v2.jpeg)