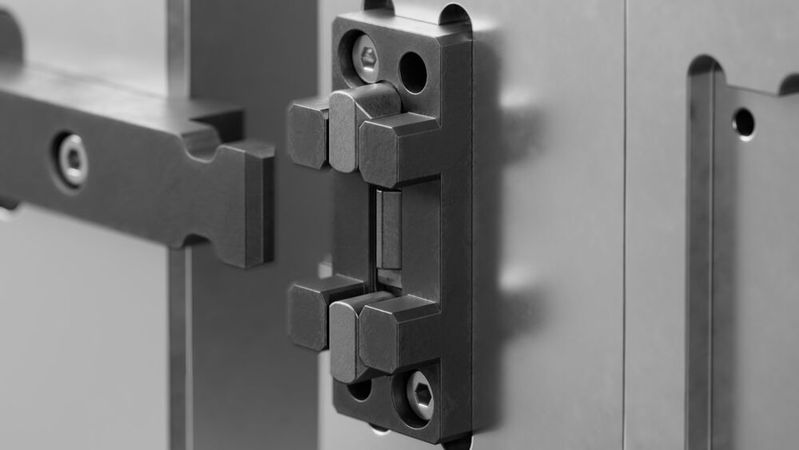

Precision moulding Groth masters complex demoulding with innovative latch locks

Related Vendors

When it comes to demoulding complex undercuts, mould makers often use multi-level tools to clear elements that obstruct the demoulding direction. At Groth in Vlotho, mould makers rely on high-quality latch locks from the extensive range of their standard parts partner, Knarr, to drive such tooling solutions.

The Claus Groth company, based in Vlotho, East Westphalia, has been manufacturing complex and technically sophisticated injection moulding tools since 1948. In addition, the plastics specialists produce injection-moulded products in their in-house moulding facility. As a family-run business, Groth is a reliable partner for clients in the automotive industry, mechanical engineering, furniture construction as well as transport technology.

The company’s production experts can respond flexibly to customer requirements — from just a few hundred parts per year to production volumes of up to two million. “We manufacture injection moulds up to a size of 800 x 600 mm,” explains Jens Strate, Managing Director of the company located in the Lipper Bergland region. “Our injection moulding machines operate with clamping forces of up to 300 tonnes. And for over 30 years, we have also been supplying our customers with assemblies and plastic-metal composites.”

Sign in or register and read on

Please log in or register and read this article. To be able to read this article in full, you must be registered. Free registration gives you access to exclusive specialist information.

Already registered? Log in here

:quality(80)/p7i.vogel.de/wcms/d2/63/d26376330f084c718f9ab83fc66eb39f/0129319680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4f/a9/4fa94db21a092a12fdb0822e3d5c8150/0129504798v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/8d/b7/8db71c3fe25cd48399bfd8faaa5e90f7/0129228188v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/44/fc4431baf22faf49f91d695e7725b0de/0129227575v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ba/ea/baea897f2d161c46f0872c77cd26fb6b/0129039787v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a6/06/a606d5e06236baca21d7f53019dedf42/0129504701v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/a8/0ba81aaff9b06473404eafd31bfbfe06/0129451471v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/34/2f344c97b0e4a9613850f3bb3b519101/0129337496v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/63/53/6353c75a9072fc20846b40065c12f724/0129533055v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b7/e0/b7e0832ad0be13fb559a7028f2ef02c7/0129386806v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5d/3c/5d3cd553a019b4033e441e61f98b23d6/0129229293v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/82/e7/82e72d20cefdef73713b584312be57d0/0129209599v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/24/84/24844705e911d0231a551255ab3a7ee7/0129505503v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ae/7c/ae7cfa25bd4cbdee97cf91514a80a569/0129333424v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/50/7e/507e92bc6eb96c6646801c23695fd698/0128867905v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/8c/cd8c3ca788be29055f3af26645fa0262/0128810840v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/c8/43/c843d8084b4db01b20506a3773a8e56d/0129505472v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/8c/528c3c99265c6d8951e6bb1dcf4ed7c2/0129224981v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/28/95/28952358db60b91461ebfda8196fad46/0129221819v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/96/16/9616c2fc580d720e8b3f91bbffcc5a01/0129504787v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/5d/9b5db33353f3e5a256e2f634ddc349c7/0129333056v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/e1/0ae1b7a9cc45bf10ebcbce27be707eda/0129230371v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f4/e9/f4e9eabb65e0b34fe9911620718ea8e2/0129055594v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/ca/f9ca9cace88200a5ec0946f193264963/0129209504v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/61/2f61dd20be68049fa2320a2e5aa860d7/0123789183v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c5/49/c54973f28495dada1c7605f913717341/0121533734v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/8f/948f81f46645691d1d90152ef605a0ae/0120806008v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/88/a2/88a2be18834640f6e34db6bcaa98da06/0129504771v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/04/3d/043d3f95c300d98d7188d2c2f0673aa5/0129365083v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0b/9e/0b9e9ae6c55036cf35f97cd4ffca9d27/0129363249v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/3e/4a3ee5cd13d05629db9d3e88aa22ff01/0129103256v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/b4/6bb456c148f06af9d65155da63665c22/0129102929v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/4d/f34d32adcd63bdf5332e4d57ae75611a/0128850501v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/7c/a2/7ca2adf016cad8d1de510c4df0ff57bc/0128810813v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/57/9c/579c8e2bcff2e800a19fcb0926e574fa/0129056117v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/4a/5f/4a5fd6bde5784db58812f15386c2126f/0126112832v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/3c/873c56a315b598e5491cef38d9ef72f1/0123364440v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/9c/6b9cab1e262f77caed8179ed3dc29807/0129104421v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/49/58/4958084fe5c4ed0a7758f7cfb3051e92/0128854986v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/a3/39a32d830d6bb6e4471c79e537c5ca52/chimei-ecologue-frosch-6000x3373v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/29/2b297a2773f13d3017fc6d49424a57b1/0127570680v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/fd/07fd8752b8d884ee69baba1b2207d82d/0129373572v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/13/ec/13ece74e59d459301ea38becf80c9706/0129200881v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fe/9b/fe9b79ee842142ff26180132de72b2d5/0129103360v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2a/7e/2a7e5ced0986e88a6c24123fba954dee/0128871141v2.jpeg)

:fill(fff,0)/p7i.vogel.de/companies/66/0e/660e93698db24/hasco-logo-or-b50.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/84400/84424/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/125700/125705/65.jpg)

:quality(80)/p7i.vogel.de/wcms/19/46/1946128e219613a59adb20ce3dbf1386/0127812088v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/bd/a8bdd76fae4c25e7af8d27b23680eda5/0127824079v1.jpeg)